Overview

Kitec Pipes are manufactured by KiTEC Industries (India) Private Limited, an ISO 9001:2015 Company.

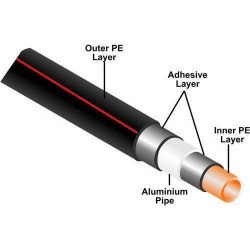

KiTEC is an aluminum and polyethylene composite that combines the best features of both materials to form a pipe that is light, strong and does not support corrosion. By combing the two materials along with adhesive layers, KiTEC pipe avoids the unaccepted thermal expansion and deformation of plastic pipe. At the same time, it retains the flexibility, frost resistance and ease of use associated with plastic.

The Unique feature of KiTEC is it’s malleability , KiTEC is easily formed into curves , can be set by hand and may require only bending springs when forming tight bends down to radius equivalent to 5 times the diameter of pipe. Unlike plastic plumbing pipes, kiTEC permanently holds whatever shape it is formed into and does not need additional clips or brackets to retain the shape of bends or curves.

KiTEC piping systems don’t corrode and will never pit or develop pin holes from aggressive water leading to premature failure. Also they do not have any effect of UV radiation in outdoor installation. There is no light transmission.

In continuous flowing plumbing and water supply applications, KiTEC can withstand multiple cycles of freezing and thawing while under pressure without up to a certain temperature. , KiTEC composite pipes provide an increased resistance to the onset of condensation or pipe sweating in a plumbing application.

1. Corrosion & scale resistance

2. Chemically inert

3. Smooth surface for better flow rate

4. Non-toxic & rust-free

2. Absorb eventual shifting movements between the plastic and the metal layers

3. likely to occur in opposite directions.

4. Give the Composite pipe, advantages of a single component pipe.

2. It limits oxygen permeability to an absolute zero.

3. It provides mechanical resistance to deformation.

4. Restricts expansion or contraction which could occur due to a change in temperature.

It also sustains more pressure because of aluminium core inside.

Our product line is highly acknowledged for its superior quality, high performance, & reliability. We are the best in this business & give a guarantee on quality of our products. We have a multidisciplinary team of professionals, that works in a close coordination with customers and bring out the best and most viable solutions.

Request A Quote

We are a professional marketing company established in 2002 with the aim to introduce high techno economic, eco friendly products.

Head Office :

Beside PNB Bank , Ambala-Chandigarh Highway Zirakpur, Punjab - 140603

Branch Office :

4th Floor , BPTP Centra One Golf Course Extension Road Sector 61, Gurgaon , Haryana - 122102

We are a professional marketing company established in 2002 with the aim to introduce high techno economic, eco friendly products.

Head Office :

Beside PNB Bank , Ambala-Chandigarh Highway Zirakpur, Punjab - 140603

Branch Office :

4th Floor , BPTP Centra One Golf Course Extension Road Sector 61, Gurgaon , Haryana - 122102

©2021 All Rights Reserved. www.kktechecoproducts.com